| Availability: | |

|---|---|

Product Description

GGT-Type Stainless Steel Wire Rope Isolator

Product introduction

The GGT-Type Stainless Steel Wire Rope Isolator represents the pinnacle of high-performance vibration, shock, and noise isolation technology. Engineered with precision-wound stainless steel cables in unique geometric configurations, these isolators provide exceptional multi-axis protection for sensitive equipment across extreme environmental conditions. Their inherent damping characteristics and all-metal construction make them ideal for applications where rubber or elastomeric isolators would degrade or fail.

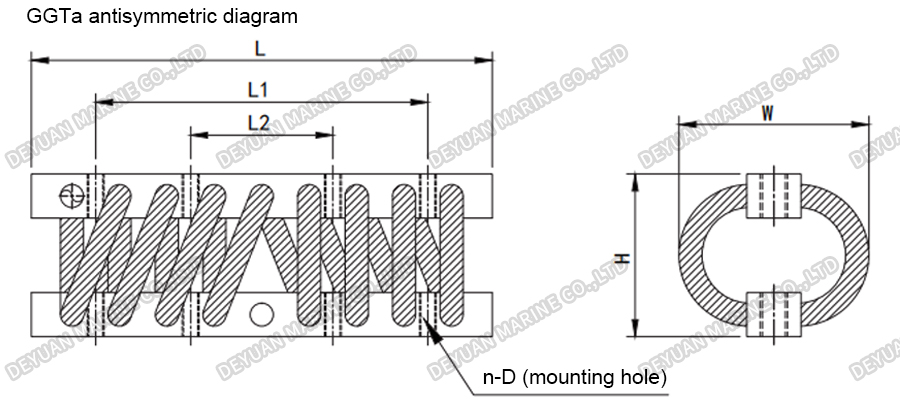

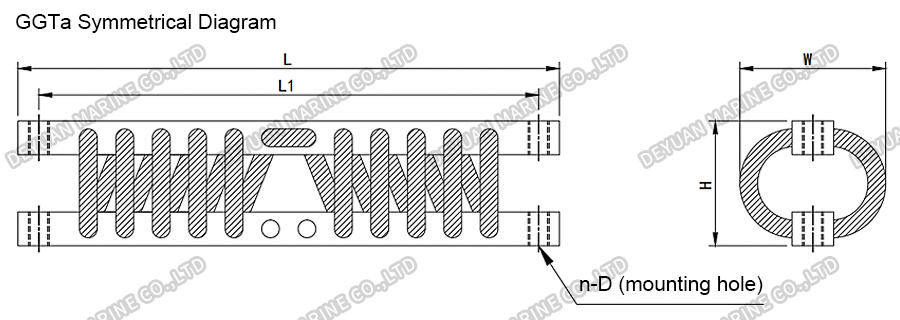

Drawing

GGT type vibration isolator basic dimensions

| Model | Dimensions(mm) | |||||

| L | L1 | L2 | H | W | n(PCS)-D | |

| GGTa0.46-18 | 80 | 69±0.3 | 18 | 27 | 4-M4 | |

| GGTa0.59-20 | 80 | 69±0.3 | 20 | 28 | 4-M4 | |

| GGTa0.64-25 | 80 | 69±0.3 | 25 | 30 | 4-M4 | |

| GGTa0.66-28 | 80 | 69±0.3 | 28 | 33 | 4-M4 | |

| GGTa0.62-30 | 80 | 69±0.3 | 30 | 36 | 4-M4 | |

| GGTa0.58-33 | 80 | 69±0.3 | 33 | 38 | 4-M4 | |

| GGTa0.25-33 | 80 | 69±0.3 | 33 | 38 | 4-M4 | |

| GGTa2.1-23 | 112 | 100±0.5 | 23 | 28 | 4-M5 | |

| GGTa2.7-25 | 112 | 100±0.5 | 25 | 30 | 4-M5 | |

| GGTa3.0-28 | 112 | 100±0.5 | 28 | 33 | 4-M5 | |

| GGTa2.8-33 | 112 | 100±0.5 | 33 | 38 | 4-M5 | |

| GGTa2.5-36 | 112 | 100±0.5 | 36 | 41 | 4-M5 | |

| GGTa2.3-38 | 112 | 100±0.5 | 38 | 43 | 4-M5 | |

| GGTa1.0-36 | 84 | 72±0.3 | 36 | 41 | 4-M5 | |

| GGTa2.5-28 | 128 | 116±0.5 | 28 | 36 | 4-M6 | |

| GGTa3.9-30 | 128 | 116±0.5 | 30 | 38 | 4-M6 | |

| GGTa4.6-33 | 128 | 116±0.5 | 33 | 41 | 4-M6 | |

| GGTa5.3-36 | 128 | 116±0.5 | 36 | 43 | 4-M6 | |

| GGTa4.3-38 | 128 | 116±0.5 | 38 | 46 | 4-M6 | |

| GGTa4.3-41 | 128 | 116±0.5 | 41 | 48 | 4-M6 | |

| GGTa9.7-34 | 128 | 116±0.5 | 34 | 42 | 4-M6 | |

| GGTa11-38 | 128 | 116±0.5 | 38 | 43 | 4-M6 | |

| GGTa12-41 | 128 | 116±0.5 | 41 | 46 | 4-M6 | |

| GGTa9.5-45 | 128 | 116±0.5 | 45 | 50 | 4-M6 | |

| GGTb30-48 | 146 | 102±0.5 | 48 | 56 | 4-M8 | |

| GGTb44-54 | 146 | 102±0.5 | 54 | 64 | 4-M8 | |

| GGTb53-59 | 146 | 102±0.5 | 59 | 71 | 4-M8 | |

| GGTb48-64 | 146 | 102±0.5 | 64 | 80 | 4-M8 | |

| GGTb44-65 | 146 | 102±0.5 | 65 | 89 | 4-M8 | |

| GGTb42-67 | 146 | 102±0.5 | 67 | 95 | 4-M8 | |

| GGTb20-67 | 146 | 102±0.5 | 67 | 100 | 4-M8 | |

| GGTb21-83 | 146 | 102±0.5 | 83 | 108 | 4-M8 | |

| GGTb51-71 | 178 | 156±0.5 | 66±0.5 | 71 | 84 | 8-M8 |

| GGTb54-75 | 178 | 156±0.5 | 66±0.5 | 75 | 90 | 8-M8 |

| GGTb55-76 | 178 | 156±0.5 | 66±0.5 | 76 | 105 | 8-M8 |

| GGTb51-83 | 178 | 156±0.5 | 66±0.5 | 83 | 108 | 8-M8 |

| GGTb43-89 | 178 | 156±0.5 | 66±0.5 | 89 | 110 | 8-M8 |

| GGTb39-105 | 178 | 156±0.5 | 66±0.5 | 105 | 121 | 8-M8 |

| GGTb72-71 | 216 | 156±0.5 | 66±0.5 | 71 | 84 | 8-M8 |

| GGTb 79-75 | 216 | 156±0.5 | 66±0.5 | 75 | 90 | 8-M8 |

| GGTb 86-76 | 216 | 156±0.5 | 66±0.5 | 76 | 105 | 8-M8 |

| GGTb 83-83 | 216 | 156±0.5 | 66±0.5 | 83 | 108 | 8-M8 |

| GGTb 68-89 | 216 | 156±0.5 | 66±0.5 | 89 | 110 | 8-M8 |

| GGTb 65-105 | 216 | 156±0.5 | 66±0.5 | 105 | 121 | 8-M8 |

| GGTb 240-90 | 178 | 156±0.5 | 66±0.5 | 90 | 105 | 8-M8 |

| GGTb 230-95 | 178 | 156±0.5 | 66±0.5 | 95 | 121 | 8-M8 |

| GGTb 220-108 | 178 | 156±0.5 | 66±0.5 | 108 | 133 | 8-M8 |

| GGTb 220-124 | 178 | 156±0.5 | 66±0.5 | 124 | 144 | 8-M8 |

| GGTb 220-137 | 178 | 156±0.5 | 66±0.5 | 137 | 156 | 8-M8 |

| GGTb 270-90 | 216 | 156±0.5 | 66±0.5 | 90 | 105 | 8-M8 |

| GGTb 270-95 | 216 | 156±0.5 | 66±0.5 | 95 | 121 | 8-M8 |

| GGTb 270-108 | 216 | 156±0.5 | 66±0.5 | 108 | 133 | 8-M8 |

| GGTb 280-124 | 216 | 156±0.5 | 66±0.5 | 124 | 144 | 8-M8 |

| GGTb 250-137 | 216 | 156±0.5 | 66±0.5 | 137 | 156 | 8-M8 |

| GGTb 440-90 | 268 | 192±0.5 | 82±0.5 | 90 | 103 | 8-M10 |

| GGTb 430-99 | 268 | 192±0.5 | 82±0.5 | 99 | 112 | 8-M10 |

| GGTb 500-109 | 268 | 192±0.5 | 82±0.5 | 109 | 135 | 8-M10 |

| GGTb 550-119 | 268 | 192±0.5 | 82±0.5 | 119 | 152 | 8-M10 |

| GGTb 480-127 | 268 | 192±0.5 | 82±0.5 | 127 | 165 | 8-M10 |

| GGTb 920-133 | 370 | 268±0.5 | 114±0.5 | 133 | 140 | 8-M16 |

| GGTb 1000-152 | 370 | 268±0.5 | 114±0.5 | 152 | 165 | 8-M16 |

| GGTb 1200-159 | 370 | 268±0.5 | 114±0.5 | 159 | 178 | 8-M16 |

| GGTb 1300-191 | 370 | 268±0.5 | 114±0.5 | 191 | 210 | 8-M16 |

| GGTb 1100-216 | 370 | 268±0.5 | 114±0.5 | 216 | 235 | 8-M16 |

GGT type vibration isolator performance parameters

| Model | Nominal load(Kg) | Static average stiffness(N/mm) | Maximum dynamic deformation(mm) | ||||||

| Mx | M⁴5 | Mz | Kx | K₄ 5 | Kz | △Sx | △S₄₅5 | △Sz | |

| GGTa0.46-18 | 1.6 | 3.0 | 4.5 | 9 | 8 | 16 | 7 | 12 | 7 |

| GGTa0.59-20 | 1 | 2 | 3 | 4.5 | 6 | 11 | 9 | 16 | 10 |

| GGTa0.64-25 | 0.8 | 1.5 | 2.5 | 2 | 3 | 7 | 14 | 18 | 12 |

| GGTa0.66-28 | 0.5 | 1 | 1.8 | 1.1 | 2.6 | 5.4 | 16 | 21 | 18 |

| GGTa 0.62-30 | 0.4 | 0.7 | 1.2 | 1.2 | 2 | 4.2 | 21 | 22 | 20 |

| GGTa 0.58-33 | 0.2 | 0.5 | 0.7 | 1.3 | 1.7 | 3.2 | 22 | 25 | 23 |

| GGTa 0.25-33 | 0.1 | 0.3 | 0.5 | 0.7 | 0.7 | 1.3 | 22 | 25 | 23 |

| GGTa 2.1-23 | 6 | 12 | 18 | 27 | 29 | 54 | 9 | 18 | 7 |

| GGTa 2.7-25 | 4 | 10 | 14.5 | 17 | 26 | 45 | 11 | 20 | 8 |

| GGTa 3.0-28 | 3 | 5 | 8.5 | 13 | 14 | 30 | 13 | 21 | 10 |

| GGTa 2.8-33 | 2 | 4 | 6 | 5.8 | 10 | 17 | 14 | 22 | 13 |

| GGTa 2.5-36 | 1.5 | 3 | 5 | 4.1 | 8 | 14 | 16 | 25 | 15 |

| GGTa 2.3-38 | 1 | 3 | 4 | 3.5 | 7 | 12 | 18 | 34 | 18 |

| GGTa 1.0-36 | 0.5 | 2 | 2.5 | 2.8 | 5 | 8 | 16 | 25 | 15 |

| GGTa 2.5-28 | 10 | 20 | 30 | 43 | 54 | 105 | 9 | 15 | 8 |

| GGTa 3.9-30 | 7 | 15 | 20 | 25 | 39 | 72 | 14 | 20 | 10 |

| GGTa 4.6-33 | 5 | 10 | 16 | 17 | 27 | 47 | 16 | 23 | 13 |

| GGTa 5.3-36 | 3 | 7 | 13 | 13 | 24 | 40 | 18 | 25 | 17 |

| GGTa 4.3-38 | 2 | 5 | 10 | 10 | 20 | 33 | 20 | 27 | 17 |

| GGTa 4.3-41 | 1.5 | 4 | 8 | 7.8 | 18 | 28 | 21 | 34 | 18 |

| GGTa 9.7-34 | 20 | 60 | 100 | 97 | 183 | 329 | 11 | 16 | 10 |

| GGTa 11-38 | 15 | 45 | 70 | 70 | 131 | 247 | 11 | 18 | 13 |

| GGTa 12-41 | 12 | 25 | 40 | 54 | 97 | 160 | 11 | 20 | 18 |

| GGTa 9.5-45 | 10 | 20 | 30 | 35 | 72 | 118 | 14 | 23 | 22 |

| GGTb 30-48 | 25 | 50 | 80 | 103 | 159 | 260 | 18 | 34 | 15 |

| GGTb 44-54 | 12 | 35 | 50 | 50 | 116 | 164 | 23 | 41 | 20 |

| GGTb 53-59 | 10 | 25 | 40 | 33 | 86 | 122 | 30 | 50 | 25 |

| GGTb 48-64 | 8 | 20 | 30 | 22 | 62 | 88 | 37 | 53 | 28 |

| GGTb 44-65 | 5 | 16 | 24 | 17 | 52 | 70 | 39 | 57 | 33 |

| GGTb 42-67 | 5 | 12 | 18 | 14 | 43 | 65 | 43 | 62 | 38 |

| GGTb 20-67 | 4 | 10 | 15 | 12 | 36 | 54 | 50 | 70 | 38 |

| GGTb 21-83 | 3 | 8 | 12 | 7.7 | 26 | 39 | 53 | 75 | 50 |

| GGTb 51-71 | 25 | 65 | 95 | 90 | 199 | 310 | 23 | 34 | 25 |

| GGTb 54-75 | 20 | 52 | 80 | 68 | 182 | 261 | 25 | 46 | 28 |

| GGTb 55-76 | 15 | 38 | 55 | 48 | 134 | 199 | 34 | 53 | 33 |

| GGTb 51-83 | 12 | 33 | 48 | 38 | 106 | 171 | 37 | 64 | 38 |

| GGTb 43-89 | 10 | 30 | 45 | 36 | 97 | 155 | 39 | 80 | 41 |

| GGTb 39-105 | 6 | 22 | 30 | 23 | 58 | 108 | 46 | 91 | 50 |

| GGTb 72-71 | 35 | 80 | 120 | 119 | 259 | 413 | 23 | 34 | 25 |

| GGTb 79-75 | 25 | 70 | 100 | 88 | 239 | 330 | 25 | 46 | 28 |

| GGTb 86-76 | 20 | 50 | 70 | 67 | 174 | 253 | 34 | 53 | 33 |

| GGTb 83-83 | 15 | 45 | 60 | 49 | 143 | 225 | 37 | 64 | 38 |

| GGTb 68-89 | 13 | 40 | 55 | 48 | 120 | 20 | 39 | 80 | 46 |

| GGTb 65-105 | 8 | 30 | 40 | 29 | 80 | 143 | 46 | 91 | 50 |

| GGTb 240-90 | 30 | 85 | 125 | 100 | 296 | 439 | 30 | 62 | 41 |

| GGTb 230-95 | 22 | 65 | 110 | 70 | 222 | 317 | 34 | 73 | 43 |

| GGTb 220-108 | 15 | 50 | 80 | 46 | 158 | 260 | 41 | 80 | 58 |

| GGTb 220-124 | 12 | 40 | 64 | 39 | 114 | 200 | 53 | 91 | 71 |

| GGTb 220-137 | 9 | 35 | 52 | 32 | 81 | 152 | 59 | 103 | 89 |

| GGTb 270-90 | 40 | 110 | 180 | 147 | 405 | 603 | 25 | 62 | 40 |

| GGTb 270-95 | 30 | 85 | 145 | 114 | 281 | 406 | 34 | 73 | 43 |

| GGTb 270-108 | 20 | 70 | 105 | 73 | 214 | 345 | 41 | 80 | 58 |

| GGTb 280-124 | 16 | 50 | 85 | 55 | 152 | 271 | 53 | 91 | 71 |

| GGTb 250-137 | 12 | 45 | 70 | 41 | 114 | 197 | 59 | 103 | 90 |

| GGTb 440-90 | 150 | 300 | 500 | 430 | 1020 | 1800 | 27 | 41 | 30 |

| GGTb 430-99 | 130 | 250 | 400 | 417 | 926 | 1402 | 32 | 53 | 35 |

| GGTb 500-109 | 70 | 200 | 300 | 256 | 588 | 1063 | 41 | 65 | 46 |

| GGTb 550-119 | 50 | 130 | 220 | 178 | 383 | 719 | 50 | 73 | 56 |

| GGTb 480-127 | 35 | 110 | 170 | 127 | 299 | 507 | 57 | 82 | 63 |

| GGTb 920-133 | 300 | 590 | 1000 | 1051 | 1916 | 2815 | 48 | 57 | 46 |

| GGTb 1000-152 | 200 | 460 | 750 | 547 | 1305 | 1922 | 59 | 73 | 53 |

| GGTb 1200-159 | 120 | 400 | 600 | 423 | 1101 | 1921 | 66 | 87 | 58 |

| GGTb 1300-191 | 70 | 290 | 450 | 213 | 731 | 1122 | 75 | 107 | 86 |

| GGTb 1100-216 | 50 | 180 | 320 | 130 | 522 | 800 | 99 | 146 | 106 |

Note 1: Mx, M45, and Mz are the nominal loads of the vibration isolator in the lateral shear, 45° compression, and vertical (z-direction) compression directions, respectively.

Note 2: Kx, K45, and Kz are the static average stiffness of the vibration isolator in the lateral shear, 45° compression, and vertical (z-direction) compression directions, respectively.

Note 3: Sx, S45, and Sz are the maximum dynamic deformations of the vibration isolator in the lateral shear, 45° compression, and vertical (z-direction) compression directions, respectively.

Note 4: Px, P45, and Pz are the maximum impact forces of the vibration isolator in the lateral shear, 45° compression, and vertical (z-direction) compression directions, respectively.

Note 5: Ex, E45, and Ez are the energy capacities of the vibration isolator in the lateral shear, 45° compression, and vertical (z-direction) compression directions, respectively.

Features

Low natural frequency, strong impact resistance, high temperature resistance, strong corrosion resistance, and easy to use and install.

Applications

Widely used in industries such as shipbuilding, aviation, aerospace, automotive, electronics, and machinery, enabling various equipment to meet standards in vibration, shock, and noise control.