| Availability: | |

|---|---|

Product Description

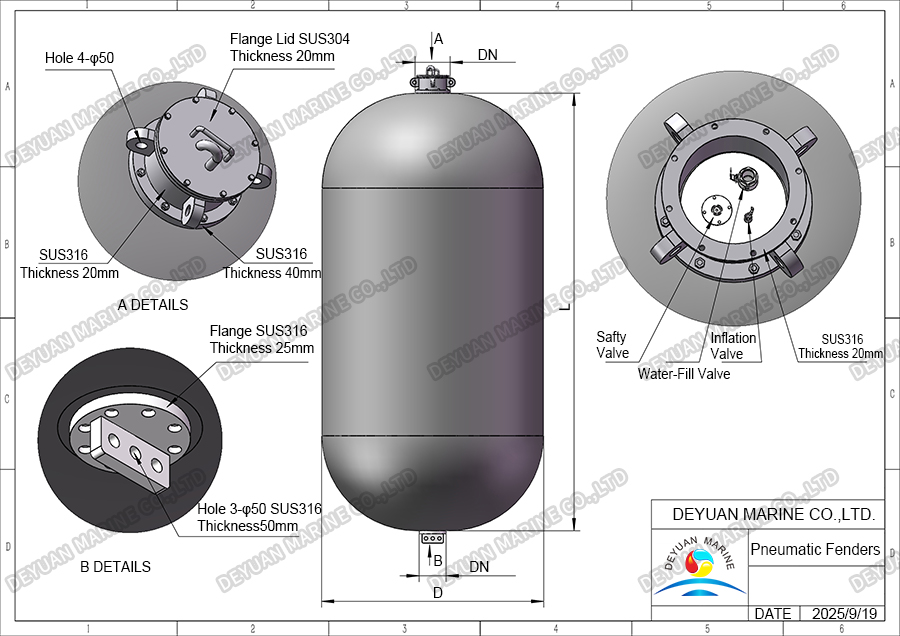

2000*4000 Submarine Pneumatic Fenders

Product Introduction

Inflatable rubber fenders (bailouts) utilize compressed air as a buffer medium to absorb the impact energy of ships, making them more flexible and resilient when berthed, thus achieving the effect of collision prevention and avoidance. They are widely used in ship-to-ship transfer operations and ship berthing operations. Compared with traditional spring-loaded rubber fenders.

Inflatable Fenders Have The Following Advantages

1.Larger impact energy absorption and smaller counter-impact force on the ship;

2.Simple installation;

3.Good elasticity and will not deform under compression;

4.Lightweight, practical, and economical;

5.No reduction in performance under inclined compression.

Inflatable rubber fenders are widely used in tankers, container ships, yachts, offshore platforms, large dry docks, naval port wharves, and large bridge piers.

Drawing

Performance Parameters

| Specifications | Initial inflation pressure 0.05 MPa Compression deformation 60% | Safety valve setting | Test pressure | Initial inflation pressure 0.08 MPa Compression deformation 60% | Safety valve setting | Test pressure | |||||

| Diameter | Length | Energy absorption | Reaction force | Surface pressure | Energy absorption | Reaction force | Surface pressure | ||||

| mm | mm | kN-m | kN | kPa | kPa | kPa | kN-m | kN | kPa | kPa | kPa |

| 500 | 1000 | 6 | 64 | 132 | -- | 200 | 8 | 85 | 174 | -- | 300 |

| 600 | 1000 | 8 | 74 | 126 | -- | 200 | 11 | 98 | 166 | -- | 300 |

| 700 | 1500 | 17 | 137 | 135 | -- | 200 | 24 | 180 | 177 | -- | 300 |

| 1000 | 1500 | 32 | 182 | 122 | -- | 200 | 45 | 239 | 160 | -- | 300 |

| 1000 | 2000 | 45 | 257 | 132 | -- | 200 | 63 | 338 | 174 | -- | 300 |

| 1200 | 2000 | 63 | 297 | 126 | -- | 200 | 88 | 390 | 166 | -- | 300 |

| 1350 | 2500 | 102 | 427 | 130 | -- | 200 | 142 | 561 | 170 | -- | 300 |

| 1500 | 3000 | 153 | 579 | 132 | -- | 200 | 214 | 761 | 174 | -- | 300 |

| 1700 | 3000 | 191 | 639 | 128 | -- | 200 | 267 | 840 | 168 | -- | 300 |

| 2000 | 3500 | 308 | 875 | 128 | -- | 200 | 430 | 1150 | 168 | -- | 300 |

| 2000 | 4000 | 384 | 916 | 138 | -- | 200 | 680 | 1380 | 172 | -- | 300 |

| 2500 | 4000 | 663 | 1381 | 137 | 175 | 250 | 925 | 1815 | 180 | 230 | 300 |

| 2500 | 5500 | 943 | 2019 | 148 | 175 | 250 | 1317 | 2653 | 195 | 230 | 300 |

| 3000 | 5000 | 1078 | 2118 | 142 | 175 | 250 | 1580 | 2878 | 180 | 230 | 300 |

| 3000 | 6000 | 1309 | 2387 | 148 | 175 | 250 | 1890 | 2906 | 196 | 230 | 300 |

| 3300 | 4500 | 1175 | 1884 | 130 | 175 | 250 | 1640 | 2476 | 171 | 230 | 300 |

| 3300 | 6000 | 1540 | 2476 | 140 | 175 | 250 | 2184 | 3176 | 182 | 230 | 300 |

| 3300 | 6500 | 1841 | 3015 | 146 | 175 | 250 | 2532 | 3961 | 191 | 230 | 300 |

Note

1. All performance parameters above are measured under static conditions;

2. The tolerance for reaction force and energy absorption is ±10%;

3. Special dimensions can be processed upon request;

4. All fender accessories are hot-dip galvanized for corrosion protection.